Rechercher

Accueil > La Recherche > Axes & Equipes > Matière Molle & Verres > Equipe : Matière Molle > Thème : Jamming, plasticity and material failure

Material failure

publié le , mis à jour le

Material failure

1. Dynamic precursors of material failure in the creep of a colloidal gel.

People involved : S. Aime (PhD), C. Ligoure (Pr), L. Ramos (DR CNRS), L. Cipelletti (Pr)

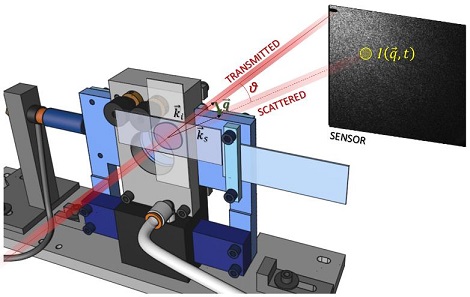

We study the microscopic dynamics of a model colloidal gel under a shear stress, using small-angle dynamic light scattering coupled to a custom-made, stress-controlled shear cell (see figure below). We find that the gel creep consists of three regimes. After an instantaneous elastic jump, in the primary creep regime the deformation increases as a power law of time, and is well described by linear viscoelasticity. This regime lasts several hours ; microscopically, the deformation deviates from affine behavior, but these non-affine dynamics are fully reversible. In the second regime, deviations are observed with respect to linear viscoelasticity, concomitant with a sharp acceleration of the non-affine dynamics, which become irreversible. These faster rearrangements precede the macroscopic rupture of the gel by thousands of seconds : thus, these ’dynamic precursors’ allow one to predict the gel failure well before the appearance of any rheological signature. The length scale dependence of the dynamics associated to these rearrangements is reminiscent of Zimm dynamics in polymers. The second regime is followed by a tertiary creep regime, where failure precursors are no longer observed, but during which the material, weakened by the strong plastic activity occurred during the secondary creep, increases its deformation rate, until a catastrophic failure occurs.

Reference :

- S. Aime, L. Ramos, J.-M. Fromental, G. Prévot, R. Jelinek, L. Cipelletti, A stress-controlled shear cell for small-angle light scattering and microscopy, arXiv:1603.06703 (to appear in Rev. Sci. Instr.).

2. Microscopic dynamics of polymeric samples under a tensile stress.

People involved : Y. Nagazi (PhD), C. Ligoure (Pr), L. Cipelletti (Pr)

We couple conventional extensional rheometry and light scattering methods to investigate simultaneously the mechanical properties and the microscopic dynamics of polyether ether ketone (PEEK), a semi-crystalline polymer, and of other polymer-based amorphous materials. Space-resolved diffusing wave spectroscopy (PCI-DWS), a recently introduced dynamic light scattering method, allows us to generate a spatial map of the sample dynamics on length scales ranging from a fraction of nm to tens of nm, and on time scales from a fraction of second to several hours.

In a first series of experiments, a PEEK sample is submitted to a series of elongation phases at a constant strain rate, each elongation phase being followed by a relaxation phase, where the sample is kept at a constant strain. During the relaxation phase, we measure the temporal evolution of DELTAsigma, the drop of the tensile stress required to keep a constant strain, as well as DELTAr^2, the mean square displacement of the chain segments, as obtained by PCI-DWS. Remarkably, we find that a simple proportionality relationship holds between the macroscopic drop of the strain and the microscopic dynamics : DELTAsigma=alpha DELTAr^2. Moreover, the prefactor alpha depends on the strain history of the sample and goes through a maximum close to but before the macroscopic emergency of plastic deformation.

In a second series of experiments, we apply a similar mechanical protocol to pristine or pre-notched cross-linked poly-dimethyl siloxane (PDMS) samples. We find that the microscopic dynamics, as quantified by DELTAr^2 measured by PCI-DWS, speeds up dramatically as the sample is increasingly strained. Remarkably, this acceleration occurs thousands of seconds before the macroscopic failure of the sample. Moreover, for both pre-notched and pristine samples, we find that the speed-up of the microscopic dynamics is enhanced around the location where a macroscopic fracture will eventually occur.

These results suggest that ’dynamic precursors’ of material failure may be detected by measuring the microscopic dynamics, paving the way to a new method to characterize and anticipate material failure.

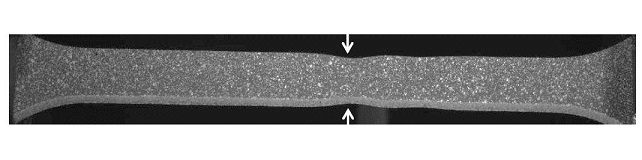

A PEEK sample exhibiting necking (arrows) after being stretched by 10%.

References : Nagazi, M.-Y. et al. Space-resolved diffusing wave spectroscopy measurements of the macroscopic deformation and the microscopic dynamics in tensile strain tests. Optics and Lasers in Engineering 88, 5–12 (2017).

3. Fracture in glassy polymers

People involved : M. George (MdC)

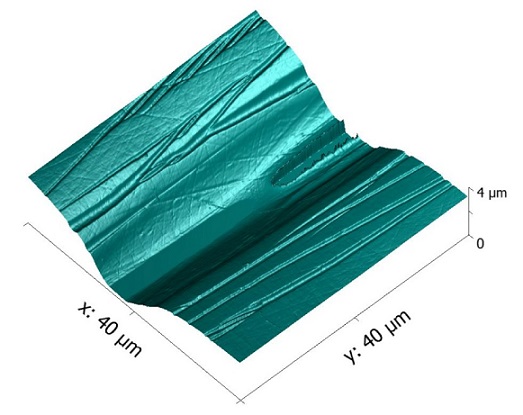

This research activity focuses on the slow crack propagation of cracks in glassy polymers. In situ AFM measurements coupled with digital image correlation allows analyzing the visco-plastic flow of the polymer at the crack tip.

AFM observation of a crack propagating in PMMA.